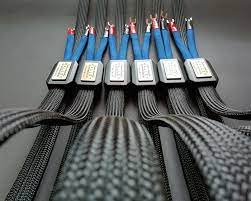

Designing of Halley took almost 10 months before it reached the final form. Each element, each type of material used for its construction, has been selected during listening sessions, with the emphasis whether it does have or not a negative impact on the sound of the wires. 12 different suppliers deliver parts to build Halley and the manual production of it takes about 16 labour hours. Halle’s conductors are thin copper ribbons that have a specified direction before they are installed inside isolation. Then they are carefully drawn through the insulation, which consists layers of compressed tapes and tunnels of woven cotton. Whole is closed in an additional external black aesthetic braid.

On both sides of the wire, cans that contain additional anti-interference shields have been mounted. Cables are terminated with spades made of uncoated (red) copper, chosen from many other endings due to their sound characteristics. Cables are made in standard lengths of 2.0 m, 2.5 m and 3.0 m. Halley is completely hand-crafted with care to avoid unnecessary stresses and excess heat during assembly. It is recommended to burn-in cables in the stereo system for about 100 first hours of use.